For anyone working with industrial automation, understanding the intricacies of specific hardware is crucial. The 6es7136-6dc00-0ca0 Wiring Diagram Datasheet serves as a fundamental document, providing essential information for the correct installation and operation of the Siemens SIMATIC S7-1500 Fail-safe Digital Output Module. This datasheet is not just a collection of lines and symbols; it's a roadmap to safely and effectively integrating this vital component into your control systems.

What is the 6es7136-6dc00-0ca0 Wiring Diagram Datasheet and How is it Used?

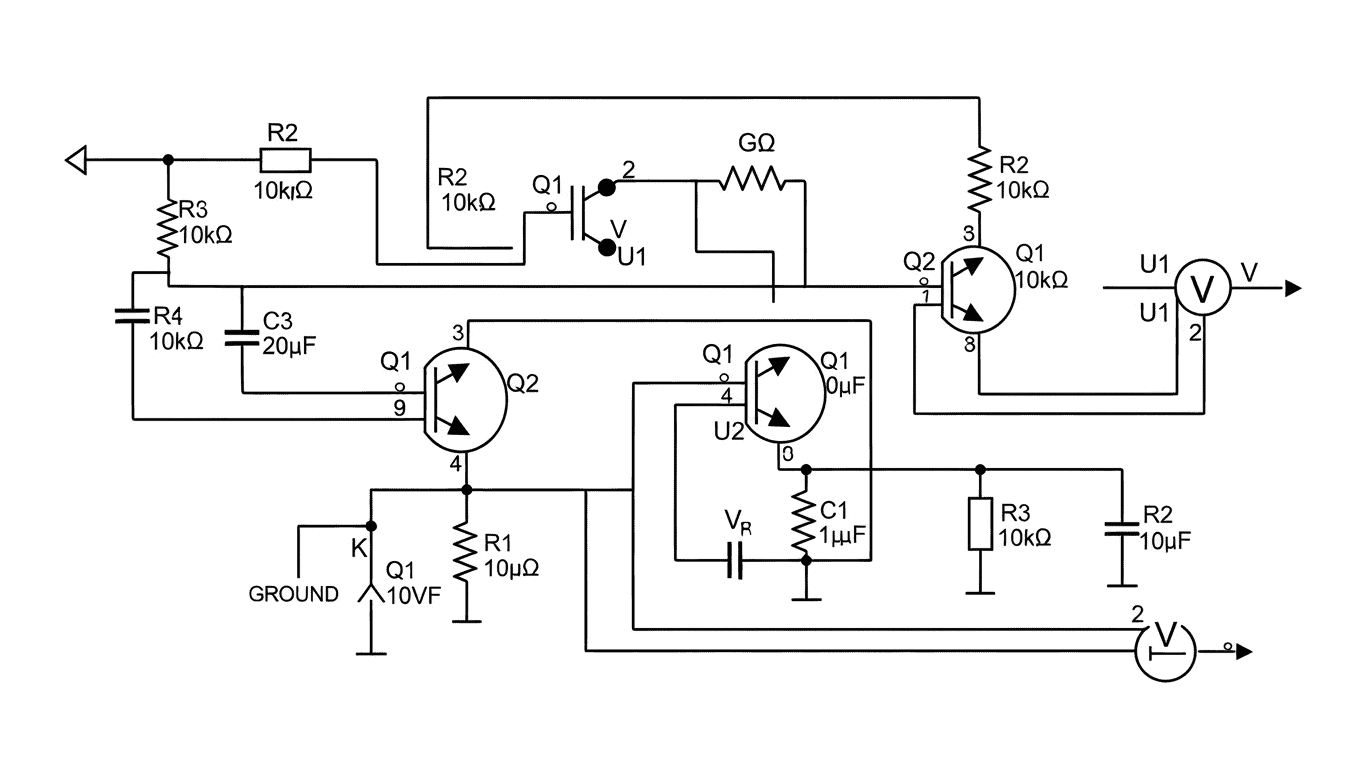

The 6es7136-6dc00-0ca0 is a fail-safe digital output module, meaning it's designed to handle safety-critical functions in automated machinery. The corresponding wiring diagram datasheet is a detailed visual and textual representation of how this module should be physically connected to other components within an industrial control system. It outlines the terminal assignments, power requirements, signal connections, and safety-related aspects of the module. Think of it as the instruction manual for making sure the electrical pathways are correctly established, preventing both operational errors and potential safety hazards.

The primary purpose of the 6es7136-6dc00-0ca0 Wiring Diagram Datasheet is to guide engineers and technicians through the installation process. It ensures that each wire is connected to its designated terminal, minimizing the risk of miswiring which could lead to equipment damage, system malfunction, or, most importantly, compromised safety. The datasheet typically includes:

- Terminal identification numbers and their corresponding functions.

- Voltage and current ratings for each connection.

- Information on grounding and shielding requirements.

- Details on safety-related wiring (e.g., connections for emergency stop circuits).

- Pinouts for any associated connectors.

Moreover, the datasheet is indispensable for troubleshooting. When a problem arises with the digital output module, the wiring diagram is the first place to turn to verify the integrity of the connections. It allows for a systematic check of each wire and terminal, helping to isolate the cause of the fault. The importance of meticulously following the 6es7136-6dc00-0ca0 Wiring Diagram Datasheet cannot be overstated , as it directly impacts the reliability, safety, and longevity of your automation system. In essence, it translates complex electrical schematics into practical, actionable steps for implementation and maintenance.

The use of the 6es7136-6dc00-0ca0 Wiring Diagram Datasheet can be broken down into several key phases of a project:

- Design and Planning: Before any physical work begins, engineers use the datasheet to plan the wiring layout, determine cable lengths, and ensure compatibility with other system components.

- Installation: Technicians refer to the datasheet during the physical wiring of the module, ensuring each connection is made precisely as specified.

- Commissioning: The datasheet is used to verify all connections are correct before powering up the system for the first time.

- Maintenance and Troubleshooting: When issues arise, the datasheet provides a reference for checking existing wiring and identifying potential connection faults.

Consider a simplified table illustrating typical terminal functions found on such a module:

| Terminal | Function | Notes |

|---|---|---|

| 1, 2 | Digital Output 1 | Sink output |

| 3, 4 | Digital Output 2 | Source output |

| L+ | Positive Power Supply | 24V DC |

| M | 0V / Ground |

To ensure your project is built on a solid foundation, familiarize yourself with the detailed information provided in the 6es7136-6dc00-0ca0 Wiring Diagram Datasheet. This resource will be your essential guide.