The 3500 Bently Nevada Datasheet is an indispensable resource for anyone involved in the critical realm of industrial machinery health. This comprehensive document provides detailed specifications and operational parameters for the Bently Nevada 3500 Machinery Health Monitoring System, a cornerstone in preventing costly failures and optimizing the performance of vital equipment across a multitude of industries.

What is the 3500 Bently Nevada Datasheet and How is it Used?

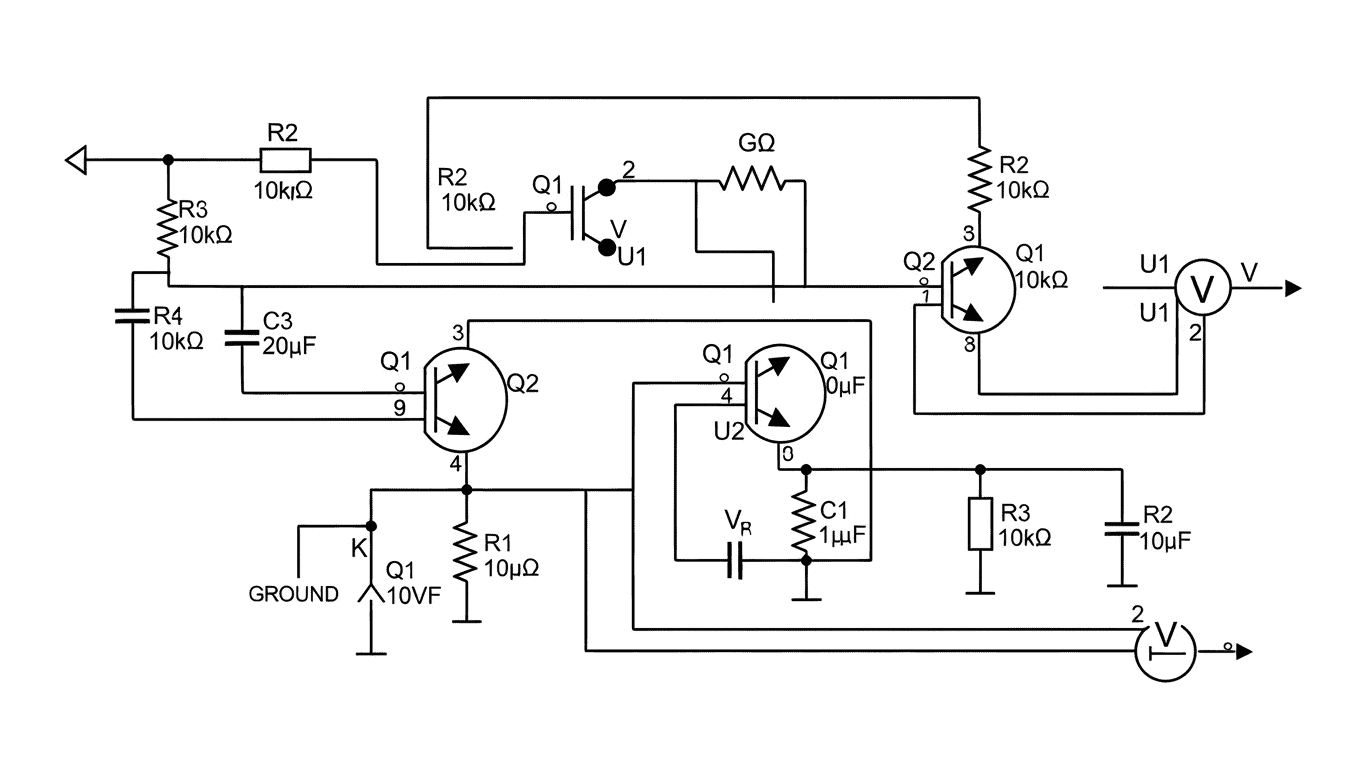

At its core, the 3500 Bently Nevada Datasheet is a technical document that outlines the capabilities, features, and specifications of the Bently Nevada 3500 system. This system is designed to continuously monitor various parameters of rotating machinery, such as turbines, compressors, pumps, and generators. The datasheet acts as a blueprint, detailing everything from the types of sensors compatible with the system to the signal processing capabilities and alarm setpoints. It's the definitive guide for engineers and technicians who need to understand precisely what the 3500 system can do and how to configure it for specific applications.

The practical application of the 3500 Bently Nevada Datasheet is multifaceted. It serves as a crucial reference during the design and selection phase of a monitoring system, ensuring that the chosen configuration aligns with the machinery's operational needs and potential failure modes. Furthermore, it's essential during installation and commissioning, providing the technical details required for accurate sensor placement, wiring, and system setup. Maintenance teams rely heavily on the datasheet for troubleshooting, understanding alarm behaviors, and verifying system performance against established benchmarks. The importance of accurately interpreting and applying the information within the 3500 Bently Nevada Datasheet cannot be overstated , as it directly impacts the reliability and longevity of critical assets.

The datasheet typically includes information on:

- System components and their functions

- Available input modules for various sensor types (e.g., proximity probes, accelerometers)

- Output capabilities for data logging and integration with control systems

- Alarm and event configuration parameters

- Power requirements and environmental considerations

For example, a typical section might detail the specifications for a specific module:

| Feature | Specification |

|---|---|

| Input Channels | 4 Proximity Probe Inputs |

| Voltage Range | -24V to 0V DC |

| Frequency Response | DC to 10 kHz |

This level of detail allows for precise system tailoring, ensuring that the monitoring capabilities are precisely matched to the demands of the machinery being protected. This meticulous approach is what makes the 3500 Bently Nevada Datasheet such a valuable tool.

To fully leverage the capabilities of your Bently Nevada 3500 system and ensure the optimal health of your machinery, consult the comprehensive 3500 Bently Nevada Datasheet. This document is your definitive resource for understanding and implementing advanced machine monitoring solutions.